Cutting too early causes raveling an effect created by the saw blade pulling the aggregate out of position leaving a messy weakened edge along the cut.

Saw cuts in concrete slabs nz.

Most of the battle can be won by simply selecting the right tools.

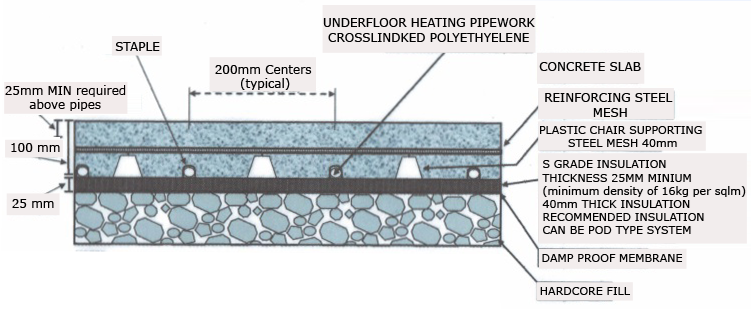

Slab for one quarter of the slab s depth see figure 2 and must not damage the dpm underneath.

One thing to be aware of before we go further.

A slab will continue to shrink and widen the control joint for years although most of the shrinkage takes place within the first year and especially within the first 90 days.

Its main function is to prevent shrinkage cracks occurring between saw cut joints.

The saw cut must be deep enough to ensure any reinforcing passing through the joint is cut through when the slab is cut.

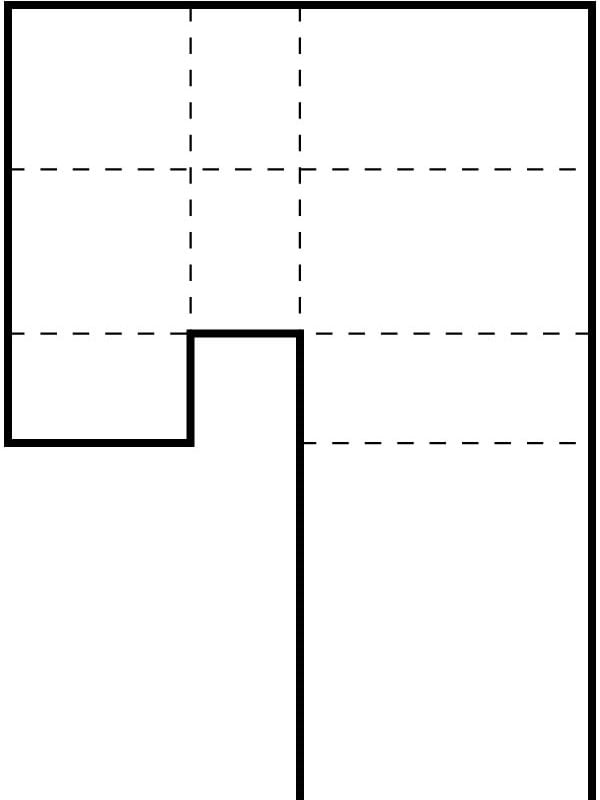

Place joints under walls or under carpet areas.

To cut concrete too thick for the saw.

Cut joints deep enough cut joints 25 of the depth of the slab.

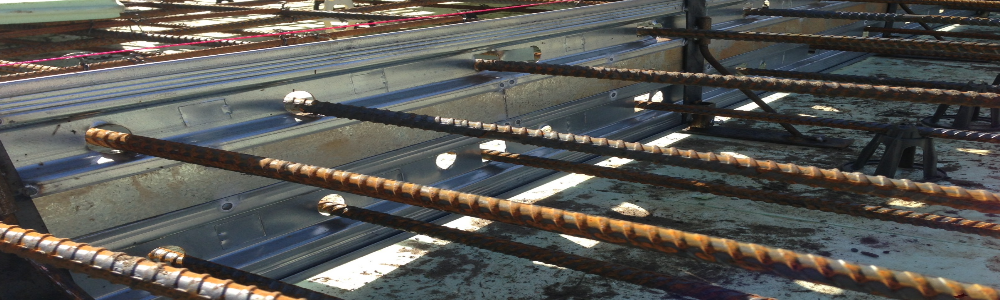

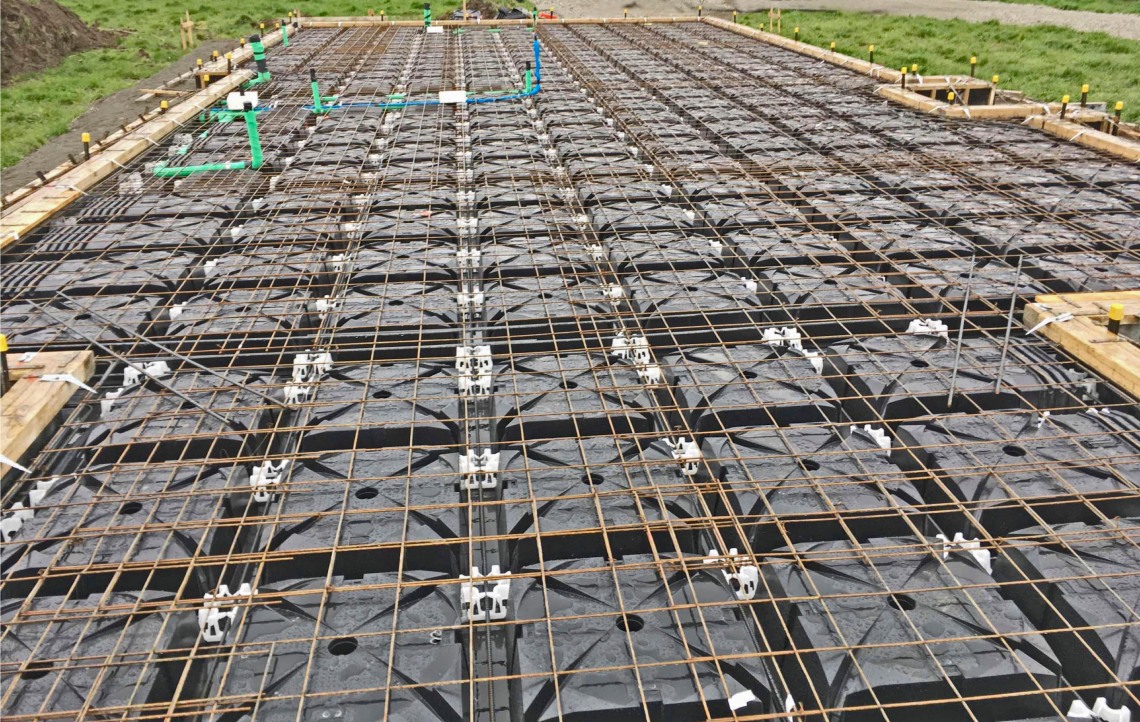

For slabs designed to nzs 3604 2011 the spacing of saw cut joints shrinkage movement joints and location of the reinforcing mesh are all important in avoiding shrinkage cracking.

Use a low rpm setting when cutting through the concrete to keep the blade from overheating and throwing chunks of concrete from the surface of the slab.

In other words when the concrete does shrink and crack the control joint is placed so that the slab will crack on a line instead of randomly across the slab.

When you are looking for saws to do relief cuts make sure that it is a down cut.

The reinforcing mesh needs to be at 30mm cover to the top of the slab see figure 2.

In winter it should be done within 48 hours.

When to saw cut concrete.

What kind of saw to use.

A good rule of thumb is to make your cut the thickness of your concrete.

How to cut joints groover tools cut joints in fresh concrete.

In summer this should be done no later than 24 hours after pouring.

Following is a rundown of common concrete cutting tasks from dinky to monster sized and the best tools and techniques for handling them.

They may be formed either by saw cutting the slab after it has hardened or by casting a crack inducer into the slab when the concrete is poured.

This method allows the placing of concrete for a complete floor area in one operation.

In order to ensure that shrinkage cracking occurs at a contraction joint a plane of weakness must be created by forming using crack inducing tapes or formers or cutting a groove to a depth of at least one quarter of the slab thickness.

Control joints that are cut into the slab should be formed within 24 48 hours after pouring depending on.

In addition to the concrete mix and the weather conditions determining when to saw concrete is based on the concrete s hardness as well as the type of cutting equipment used to make the saw cuts.

However if the cut can be formed early enough by a suitable grooving tool or early age saw cutting some.

If of your slab s thickness doesn t reach 1 make sure you still cut at least a 1 depth.

The prospect of cutting concrete can be daunting but it doesn t have to be.